Set up latex, set up adhesive, set up resin and old product can hamper the productivity of a tank truck wash facility. A-ONE has invested heavily in solutions to this ongoing tank cleaning problem. Below are several techniques for using our vat additives and our solvent strippers to make these difficult cleans profitable cleans.

All of the techniques listed in this post assume the only residue remaining in the tank is dry, hardened product that is stuck to the metal and cannot be rinsed, or pressure washed (3000psi). We recommend trying to cut X’s or lines with the pressure washer in the set-up material so the cleaning agent employed can penetrate the skins in more places.

Using heated vat water base latex strippers are a great option if the equipment is available. Dyna-Strip Powder Latex Stripper with Dyna-Strip 20/20 Resin and Latex Skin Cutter heated to 185˚F dissolves set up latex in much less time than manually scrapping it out of the tank. Normally, a 45 minute to 1-hour wash cycle will strip away set up latex or resin. However, every now and then they don’t come clean. Then what? Keep reading for some tricks of the trade that can prevent long hours of hand labor.

- Run the wash cycle longer

If you noticed that the 45-minute run cycle did soften the set-up product, but it still won’t come off, you may need to run the wash cycle longer. If you don’t want to waste the bay time running another hour or two, scrape a small sample from the tank and soak the sample in the hot vat solution for another hour or two as a bench test while you clean another trailer. We have firsthand testimonials of customers running set up latex containers 5-6 hours using alternating strainer baskets. These same containers were being hydro blasted 6-10 hours per tank. In many cases, the long run time pays off if you have the bay availability. It also beats scraping for 10 hours too! - Soak the trailer in the hot vat liquid

Many wash facilities don’t have the bay capability to let a tank sit in the bay and run a 6-hour wash cycle. An effective alternative to longer run times is letting a small portion of the wash solution soak in the tank out in the yard.

Let’s assume you did the first 45-minute wash cycle and it softened up the set-up product but still too hard to pressure wash in a timely manner. Consider reconnecting the hot vat wash and spinning the tank another 15 minutes to get the tank temperature back near 185 ˚F. Then, stop the wash and return all but around 20 gallons of vat solution back to the vat. Next, seal the tank up tight without rinsing and set it out in the hot sun.The hot vat solution that has started to penetrate the set-up product will continue to soften as long as you don’t let the tank breathe. After the tank sits for several hours, bring it back in and run it again. You will see a major difference.

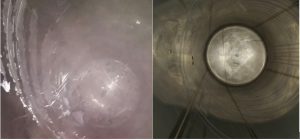

Before and after of a tank containing latex skin that was clean with our Dyna-Strip 20/20 and Dyna-Strip Powder Latex - Skin Cutter Presoak

Complete step II but Presolve the tank with 4 gallons of Dyna-Strip 20/20 before you close it up and park it outside. The extra skin cutter will really penetrate in the hot environment inside the trailer. - Solvent Stripper #1

If your facility does not have a hot vat dedicated for latex stripper but you have Presolving capability, Presolve the set-up tank with Dyna-Strip 777 and let the 777 stay in the tank. Button the tank up and park it for a few hours to allow the chemical to work. A better alternative is using an Eliminator Kit with 777 for a 30 minute circulation of the solvent before you button up the tank and park it. After you let the tank sit for a few hours, bring it in, and drain the 777 for reuse (if applicable). Then, cold water flush the tank and soap it out cold (using the Presolve pump or a one pass wash system cold). Test to see how well the product is dissolved and decide if it can be quickly pressure washed or if it needs a hot detergent wash. - Solvent Stripper #2

Another solvent stripper technique is to use the Eliminator Kit along with Dyna-Strip 4000 to circulate a small amount of this latex dissolving solvent in the tank. Heating the tank coil while circulating the Dyna-Strip 4000 produces excellent results. Just be sure not to heat the Dyna-Strip 4000 over 150 ˚F to prevent damage to the Eliminator Kit. Then, follow the rinsing procedures in section IV.